Machine tool cables are essential for industrial and manufacturing applications, providing power, control signals, and data transmission between machine components.

Our CNC machine tool wire brings together the world's top scientific and technological strength, using a unique design concept, the perfect integration of traditional technology and modern technology. Every component is strictly screened and inspected to ensure that you are provided with the best quality products.

Our CNC machine tool wire has excellent performance, high speed, high precision and high stability to make your production process smoother.

Adhering to the concept of green environmental protection, we are committed to contributing to the sustainable development of the earth. Our CNC machine tool wire uses energy efficient design to reduce energy consumption, reduce waste emissions, and make your production more environmentally friendly.

We know that each customer's needs are unique, so we provide customized services to tailor the best CNC machine line for you. Let's join hands to create a better future!

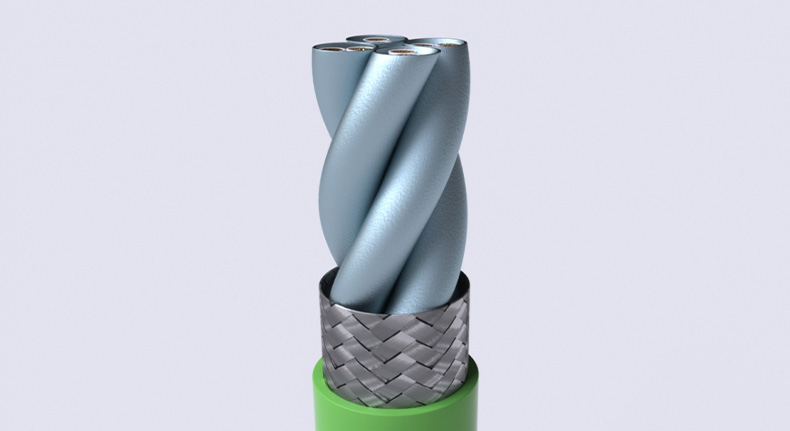

Complete in specifications, high flexibility application, suitable for multiple areas. Cable with wear resistance, high flexibility, bend resistance, oil resistance, tensile resistance, shallow water resistance, acid and alkali resistance, aging resistance, weather resistance and other characteristics. Can be customized upon request.

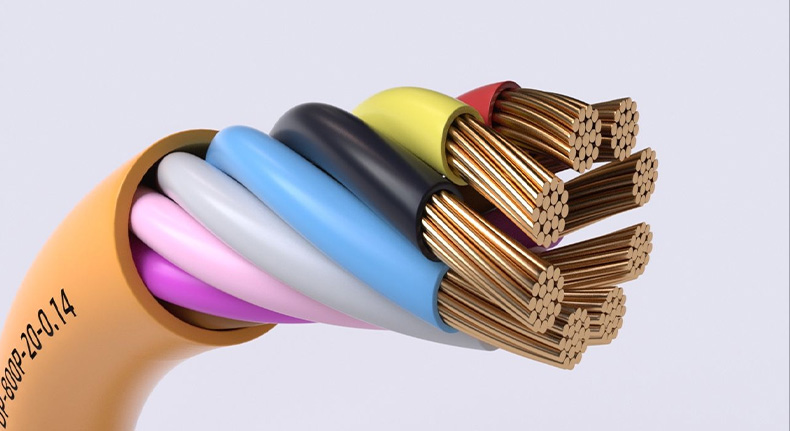

● Power cable: used for main power transmission of machine tool equipment, requiring high voltage resistance and strong heat resistance, usually with shielding layer to reduce electromagnetic interference.

● Control cable: used to transmit control signals inside the equipment, requiring high flexibility and wear resistance, often used in dynamic application scenarios such as machine tool arms and drag chains.

● Signal cable: transmits low voltage signals, used for sensors, encoders and other equipment, focusing on anti-interference and accuracy.

● Data cable: used for high-speed data transmission, such as the network or bus system connecting CNC machine tools, which needs to meet high-frequency signal transmission requirements.

● Drag chain cable: designed for frequent bending scenarios, with extremely high flexibility, fatigue resistance and long service life.

● Special cables: customized cables such as oil-resistant, high-temperature-resistant, waterproof, and fire-resistant, used in complex or extreme environments.

Each cable has different technical characteristics and material selections according to the specific application scenario.

Machine tool cables are used in CNC machines, robotic systems, automated production lines, and heavy machinery. Designed to withstand harsh environments, these cables ensure precise control and reliable communication in power supply, signal transmission, and data communication, facilitating efficient and accurate operations in various industrial processes.

News

Shielded Cat5 vs. Unshielded Cat5: Which One Should You Choose?

Jan. 27, 2025

Dec. 23, 2024

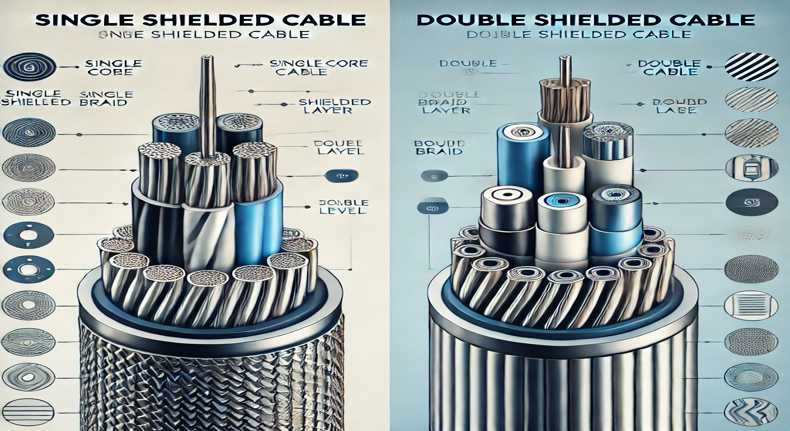

What is the Difference Between Single and Double Shielded Cable?

Dec. 13, 2024

Get Your

Exclusive Quote

Product Category