Thermoplastic polyester elastomer (TPEE) is also known as polyester rubber, is a kind of linear block copolymer containing PBT (polybutylene terephthalate) polyester hard segment and aliphatic polyester or polyether soft segment. PEE has the excellent elasticity of rubber and the machinability of thermoplastics, excellent bending fatigue resistance, excellent instantaneous high temperature performance, excellent impact resistance (especially at low temperature -- -40℃), good tear resistance and wear resistance, excellent chemical resistance and weather resistance, excellent electrical properties, and excellent charge bearing capacity. Due to its outstanding mechanical strength, excellent resilience and wide use temperature and other comprehensive properties, TPEE has been widely used in automotive parts, hydraulic hoses, cables and wires, electronic and electrical appliances, industrial products, sporting goods, biological materials and other fields.

TPEE (thermoplastic polyester elastomer) is a high-performance thermoplastic elastomer material with the following properties and uses:

Features:

1. High strength and elasticity: TPEE has high tensile strength and bending elastic modulus, as well as good resilience and toughness. This allows it to withstand high loads while maintaining good elasticity.

2. Chemical resistance: TPEE has good chemical resistance and can resist the erosion of most acids, alkalis, salts and oils. This makes it a good application in many chemical environments and fluids.

3. Temperature resistance: TPEE can be used in a wide temperature range, and its high temperature resistance is particularly excellent. It can still maintain good mechanical properties and stability at high temperature.

4. Processing performance: TPEE has good processing performance, can be melted at high temperature, and is sensitive to shear, easy to process thin-walled products.

5. Electrical insulation: TPEE has good electrical insulation performance and can be used as an insulating material for cables or other electronic products. Its dielectric constant and dielectric loss are low, and it can maintain stable electrical performance at higher frequencies.

6. Flame retardant: TPEE has excellent self-extinguishing and flame retardant, which can effectively inhibit combustion and prevent the spread of fire.

7. Wear resistance and fatigue resistance: TPEE has good wear resistance and fatigue resistance, and can maintain its performance under repeated bending and friction conditions.

Application:

1. Automotive industry: TPEE is widely used in the automotive industry in engine parts, seals, electrical harness sheathing, oil pipes, etc. Its high strength, high temperature resistance and oil resistance meet the stringent requirements of the automotive industry.

2. Petroleum and chemical industry: The chemical corrosion resistance of TPEE makes it widely used in the petroleum and chemical industry in pipeline seals, valve components, pump parts, etc.

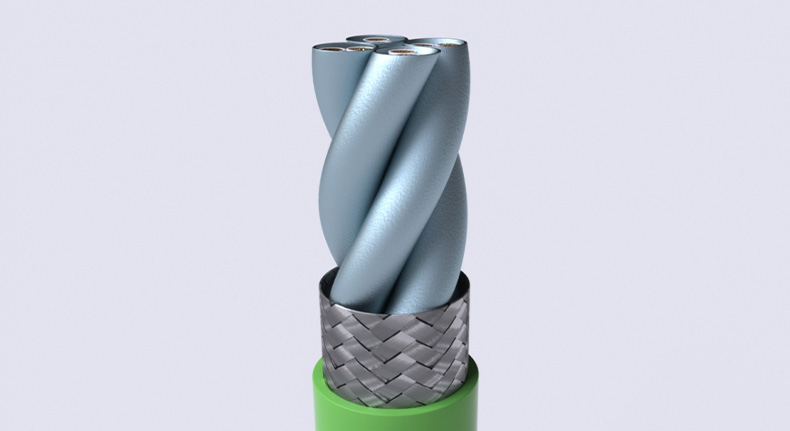

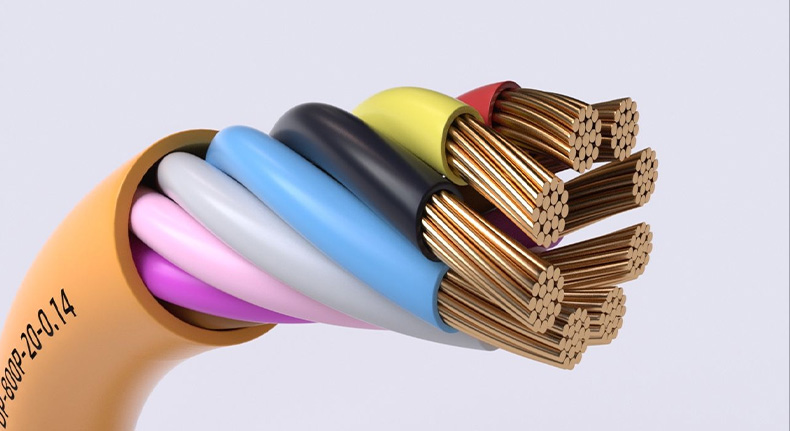

3. Wire and cable industry: Due to TPEE's electrical insulation performance, temperature resistance and chemical resistance, it is used as an insulating layer, sheath layer or filling layer in the wire and cable industry. Especially in cables that need to withstand high temperatures, chemical corrosion or mechanical stress, TPEE is an ideal choice.

4. Other fields: In addition to the above application fields, TPEE can also be used in aerospace, construction, medical equipment, sports equipment and other fields. Its high performance and flexibility allow it to perform well in a variety of environments and applications.

In general, TPEE is a high-performance thermoplastic elastomer material, with high strength, high temperature resistance, chemical corrosion resistance and other excellent properties, widely used in the cable industry, can effectively improve the service life and stability of the cable. At the same time, it can also be applied to many fields such as the automotive industry, petroleum and chemical industry.

News

Shielded Cat5 vs. Unshielded Cat5: Which One Should You Choose?

Jan. 27, 2025

Dec. 23, 2024

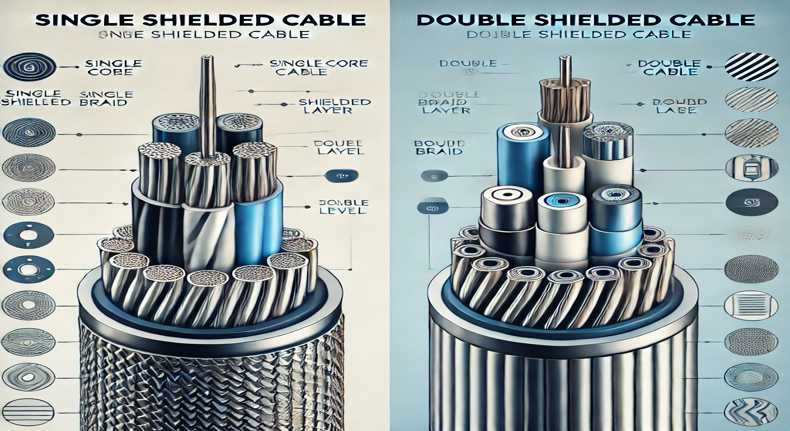

What is the Difference Between Single and Double Shielded Cable?

Dec. 13, 2024

Get Your

Exclusive Quote

Product Category