High density polyethylene (HDPE) is a white powder or granular product. Non-toxic, tasteless, crystallinity is 80% ~ 90%, softening point is 125 ~ 135℃, the use temperature can reach 100℃。 It’s hardness, tensile strength and creep properties are better than those of low density polyethylene. With the character of good wear resistance, electrical insulation, toughness and cold resistance,good chemical stability. At room temperature, it’s insoluble in any organic solvent, acid, alkali and various salts corrosion resistance. The film has little permeability to water vapor and air, and low water absorption. The aging resistance is poor, the environmental stress cracking resistance is not as good as low-density polyethylene, especially the thermal oxidation will reduce its performance, so the resin must be added to antioxidants and ultraviolet absorbers to improve this deficiency. When applied, it should be noted that the heat deformation temperature of high-density polyethylene film is low under stress.

HDPE (High density polyethylene) is a thermoplastic that is widely used in various fields due to its excellent properties and wide range of uses. The following are the properties and uses of HDPE:

Features:

1. High density: HDPE has high density, hard texture and good impact resistance and wear resistance.

2. Electrical performance: HDPE has good electrical insulation properties and is often used in the manufacture of wire insulation.

3. Chemical stability: HDPE has good tolerance to most acids, alkalis, salts and other chemicals, and is not easy to be corroded.

4. Processing performance: HDPE is easy to process, can be molded by injection molding, extrusion, blow molding and other processes, and it is not easy to produce internal stress during molding.

5. Temperature resistance: HDPE has good heat resistance and can maintain its performance in a wide temperature range.

6. Low water absorption: The water absorption rate of HDPE is low, and it can maintain good waterproof performance.

Application:

1. Packaging field: HDPE can be made into various packaging containers, such as food packaging, cleaning supplies packaging, etc.

2. Pipeline system: Due to its pressure resistance, corrosion resistance and wear resistance, HDPE is often used in the manufacture of water pipes, cable pipes and other pipeline systems.

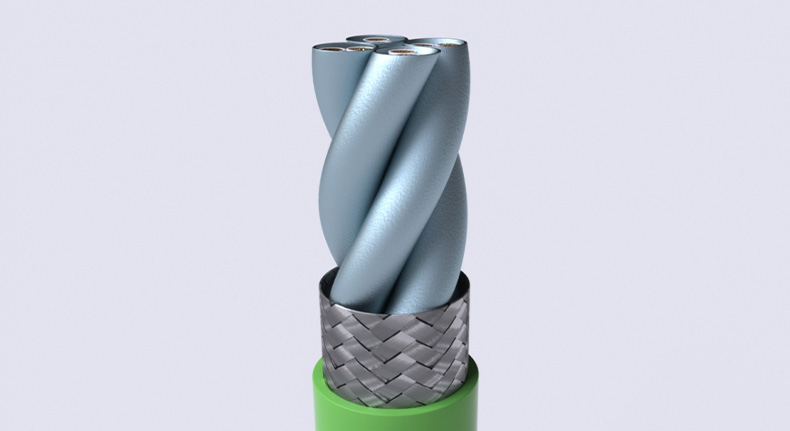

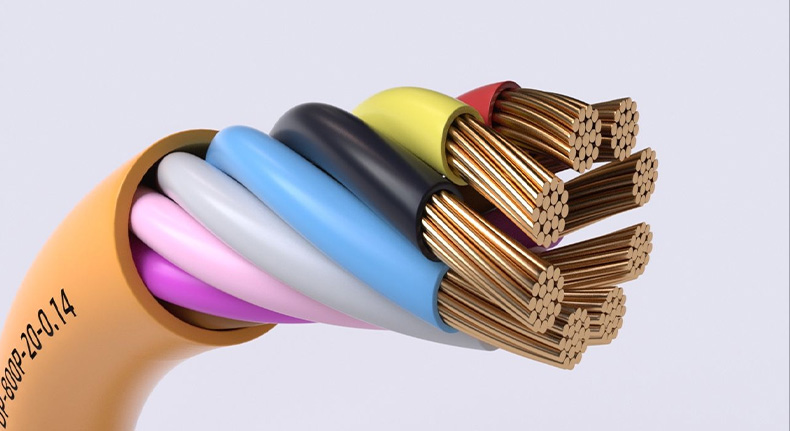

3. Wire and cable: HDPE can be used as the insulation layer and sheath layer of wire and cable, with good electrical insulation performance and chemical resistance. In addition, its low-smoke halogen-free characteristics also make it one of the ideal materials for fireproof cables.

4. Agricultural field: HDPE can be made into agricultural film, irrigation pipes, etc., which helps to improve agricultural production efficiency.

5. Other fields: HDPE can also be used in medical equipment, sports equipment, office supplies and other fields.

In the cable industry, HDPE is widely used in the manufacture of various wires and cables as an insulating layer and sheath layer. Due to its excellent electrical insulation properties, chemical resistance, low smoke halogen-free characteristics and processing properties, HDPE can meet the various performance requirements of cables. In addition, the high density and wear resistance of HDPE also make cable products more durable and able to withstand greater mechanical stress. In general, HDPE has important application value in the cable industry, which can improve the safety performance and service life of cables.

News

Shielded Cat5 vs. Unshielded Cat5: Which One Should You Choose?

Jan. 27, 2025

Dec. 23, 2024

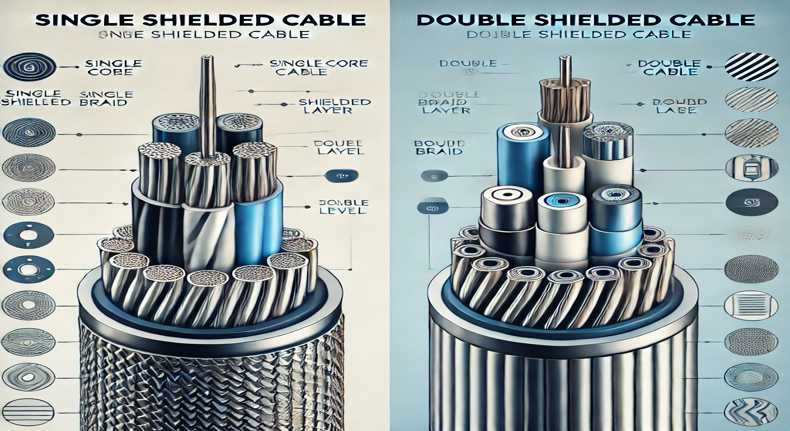

What is the Difference Between Single and Double Shielded Cable?

Dec. 13, 2024

Get Your

Exclusive Quote

Product Category